NEWS

What is the purpose of the O-ring kit?

Release time:2024-11-06

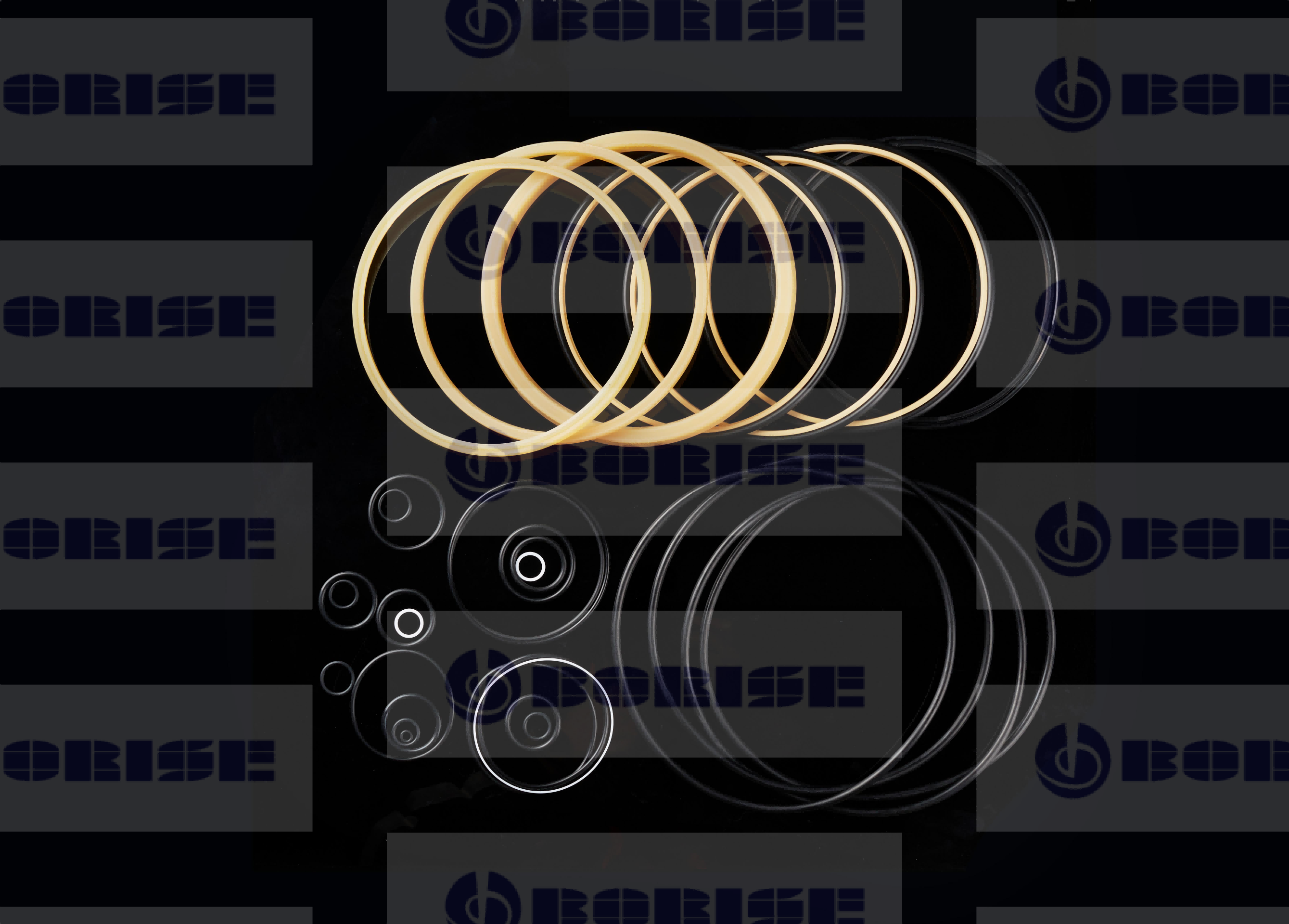

Introduction to O-Ring Kits

O-ring kits are fundamental tools in the realm of engineering and manufacturing, serving as essential components for sealing and protection. Originating in the 20th century, these kits have become indispensable due to their simplicity and effectiveness. The standard O-ring kit, including the widely sought-after China O-ring kit and high-quality O-ring kit variants, comprises various elastomeric rings used to create a leakproof seal between two components. This introduction delves into their historical background, emphasizing their critical role in modern industries.

● Definition and Historical Background

An O-ring kit is a collection of elastomeric rings used to mechanically seal gaps between two components in a variety of applications. The concept of the O-ring is simple yet powerful, having been developed in the early 20th century and gaining widespread use soon thereafter. As an everlasting solution in manufacturing and repair, the demand for these kits has continuously surged, highlighting the importance of finding a reliable O-ring kit manufacturer or supplier for ensuring quality and performance.

● Importance in Modern Engineering and Manufacturing

In today's fast-paced engineering world, the O-ring kits have gained unprecedented significance. They are pivotal in ensuring the efficiency and safety of countless systems and machinery, ranging from domestic appliances to complex industrial machines. These kits, often sourced from reputable O-ring kit factories, serve as critical components in maintaining the integrity of products, preventing leaks, and ensuring the smooth operation of mechanical parts. Their role underscores the necessity to choose a high-quality O-ring kit for optimal performance.

Composition and Materials of O-Ring Kits

The effectiveness of an O-ring kit is significantly determined by the materials used in its manufacture. These materials dictate the applications and environments where the O-rings can function optimally.

● Common Materials Used (NBR, Silicone)

O-ring kits are typically composed of materials like Nitrile Butadiene Rubber (NBR) and Silicone, each possessing unique properties that cater to different applications. NBR is favored for its resilience to oils and hydrocarbons, making it suitable for automotive and industrial contexts, while Silicone is appreciated for its thermal stability and flexibility, ideal for extreme temperature conditions. This versatility makes these kits a staple for any reliable O-ring kit supplier.

● Material Properties and Their Applications

The choice of material for O-ring kits affects their durability, resistance to environmental factors, and overall performance. NBR's oil resistance and robustness make it a popular choice for hydraulic and fuel systems, while Silicone's ability to withstand temperature variations is perfect for aerospace and medical applications. Understanding these properties helps in selecting the right type of O-ring for specific needs, ensuring efficiency and longevity, and thus emphasizing the need for a knowledgeable O-ring kit manufacturer.

Types and Varieties of O-Ring Kits

The market offers a wide array of O-ring kits, each designed to meet specific requirements and applications.

● Range of Sizes and Specifications

A typical O-ring kit contains a diverse selection of O-rings in various sizes and thicknesses. This assortment is crucial for accommodating the different sealing needs that arise in diverse industries. Kits may range from containing a few dozen pieces to over a hundred, each precisely manufactured to meet specific technical standards. The availability of comprehensive kits allows users to find O-rings that perfectly fit the dimensions required for their applications, emphasizing the importance of working with a versatile O-ring kit supplier.

● Different Types of Kits Available in the Market

O-ring kits are available in several variations, catering to specific industries. From general-purpose kits to those designed for high temperatures or high-pressure environments, the options are extensive. Specialized kits are often developed by leading O-ring kit factories to address niche demands, offering solutions tailored to specific challenges such as chemical exposure or stringent sanitary requirements.

Applications of O-Ring Kits in Industry

The use of O-ring kits spans virtually every sector, from sealing hydraulic components to ensuring the integrity of scientific instruments.

● Use in Sealing Applications

O-ring kits are primarily utilized in creating leakproof seals, a critical function in both static and dynamic applications. They prevent the escape of liquids and gases in equipment ranging from household plumbing systems to complex aerospace machinery. The reliability and efficiency of these kits in various sealing applications highlight their indispensable nature in maintaining the operational standards of equipment.

● Importance in Hydraulic and Pneumatic Systems

In hydraulic and pneumatic systems, O-rings are vital in preventing fluid or air leaks, thereby ensuring the systems operate efficiently and safely. These environments often demand high durability and resistance to pressure, temperature, and chemical exposure, requirements that high-quality O-ring kits are designed to meet. Their implementation in such critical systems underscores the expertise and technology employed by leading O-ring kit manufacturers.

Advantages of Using O-Ring Kits

O-ring kits offer numerous benefits that contribute to their status as a fundamental resource in engineering and maintenance.

● High-Pressure Environment Suitability

One of the significant advantages of O-ring kits is their capability to perform under high-pressure conditions. The design and material composition of O-rings allow them to maintain their sealing functions even in extreme environments, where other gasket types might fail. This attribute makes them a preferred choice for applications in automotive, aerospace, and industrial hydraulics.

● Versatility in Various Engineering Contexts

The adaptability of O-ring kits is another feature that enhances their appeal. They can be used in a myriad of applications, from simple household devices to complex industrial machinery, due to their robust and flexible nature. This versatility is what drives the continuous advancements in their designs and materials, as seen in the products of innovative O-ring kit suppliers.

O-Ring Kit's Role in Maintenance and Repair

O-ring kits are invaluable in maintenance and repair operations, providing quick and effective solutions for sealing challenges.

● Ease of Use in Urgent Repair Situations

In urgent situations where time is of the essence, the availability of a comprehensive O-ring kit can be a game-changer. These kits facilitate rapid repairs by providing the right size and type of O-ring, preventing prolonged downtimes and ensuring minimal disruption to operations. This ease of use and accessibility is why many businesses keep a stock of O-ring kits from reliable factories as part of their maintenance toolkit.

● Extending the Lifespan of Machinery Components

The proper use of O-ring kits not only seals components effectively but also extends the lifespan of machinery by preventing leaks that can cause wear and damage. By ensuring components remain sealed, O-rings reduce the risk of malfunctions, ultimately saving on repair and replacement costs. Their role in enhancing the durability of machinery components further solidifies their status as essential tools in maintenance and repair.

Kesaria's O-Ring Kits: A Closer Look

Kesaria is a prominent name in the world of O-ring kits, known for its quality and innovation.

● Overview of Kesaria's Product Offerings

Kesaria Rubber Industries offers a diverse range of O-ring kits, tailored to meet both general and specific industry needs. The company’s kits are renowned for their precision and durability, catering to a wide spectrum of applications. Kesaria prides itself on its ability to deliver high-quality products that adhere to international standards, making it a trusted O-ring kit manufacturer and supplier.

● Distinct Features of Kesaria's O-Ring Kits

Kesaria’s O-ring kits are characterized by their meticulous design and high-performance materials. Featuring items like the 5A, 5B, and 5C repair kits, these products are available in both NBR and Silicone, accommodating various sealing requirements. The organization within the kits ensures that each O-ring is easily accessible, making them user-friendly and efficient solutions for sealing challenges.

Selecting the Right O-Ring Kit

Choosing the appropriate O-ring kit is crucial for achieving optimal sealing performance.

● Factors to Consider When Choosing an O-Ring Kit

When selecting an O-ring kit, several factors must be considered, including the material composition, size range, and the specific application requirements. It's important to ensure that the O-rings are compatible with the substances they will encounter, such as chemicals or oils. Other considerations include the operating temperature and pressure, necessitating a detailed understanding of the technical specifications provided by the O-ring kit factory.

● Importance of Compatibility and Durability

Compatibility and durability are paramount when selecting an O-ring kit. A high-quality kit ensures that O-rings can withstand the environmental conditions they will face, providing reliable sealing over an extended period. This durability translates to long-term cost savings and operational efficiency, underscoring the importance of choosing a reputable O-ring kit supplier.

Future Trends in O-Ring Kit Technology

The field of O-ring technology is continually evolving, with advancements aimed at enhancing performance and expanding applications.

● Innovations in Material Sciences Impacting O-Rings

Recent developments in material sciences are leading to the creation of O-rings with enhanced properties, such as increased chemical resistance and broader temperature ranges. These innovations make O-ring kits even more versatile and capable of tackling complex sealing challenges across industries. Staying abreast of these trends is essential for O-ring kit manufacturers to remain competitive and meet the dynamic demands of modern engineering.

● The Evolving Role of O-Rings in Emerging Technologies

As technology advances, the role of O-rings is expanding into new fields, such as renewable energy, robotics, and advanced manufacturing. These sectors present unique sealing challenges that require innovative solutions, driving the development of specialized O-ring kits. The ongoing evolution of O-ring applications highlights the necessity for continuous innovation within this essential industry.

Conclusion: The Essential Nature of O-Ring Kits

O-ring kits are fundamental tools that serve a critical function in ensuring the efficiency and reliability of mechanical systems. Their versatility, durability, and adaptability make them indispensable in a wide range of applications, from industrial machinery to domestic appliances. By providing effective sealing solutions, O-rings enhance the performance and lifespan of components, underscoring their importance across industries. The ongoing advancements in O-ring technology promise even greater capabilities and applications, ensuring their continued relevance in the future.

● Company Introduction: BORISE

Hangzhou Ruiwei Machinery Equipment Co., Ltd., under the brand BORISE, stands as a leader in the sealing systems industry. Specializing in the research, design, and production of high-quality oil seals for construction machinery, the company integrates German technology to develop resilient polyurethane oil seals and wear-resistant step seals. BORISE excels in meeting diverse sealing needs, making it a trusted supplier for major brands in China. With a focus on quality and innovation, BORISE is committed to advancing the future of sealing technology.

- About BORISE

- Company Profile

- About Team

- On Service

- Company Chronology

- Join Us

- technical support

- Industry Solutions

- Technical Support Analysis

Copyright © 2022,All right reserved © Borise Technology Co., Ltd

Hot Products - Sitemap

case hydraulic cylinder rebuild

, seal kit boom pc200 8

, seal kit boom cylinder

, kubota hydraulic cylinder rebuild

, dust wiper seal

, hydraulic seal repair