- In domo

-

Productus

-

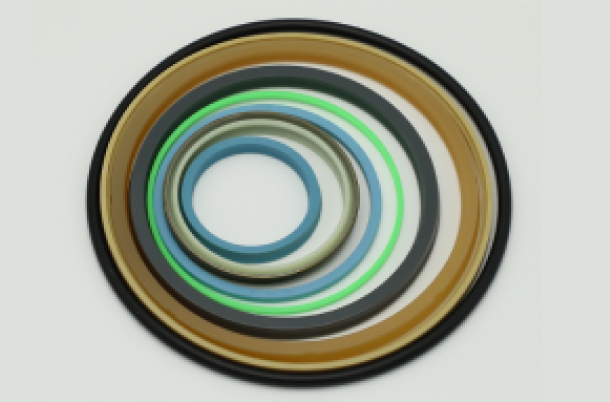

Hydraulicorum Rudia Sigillum Ornamentum

- Diaphragma enim Hyd. Ruptor

- Sigillum ornamentum in furukawa ruptor

- Sigillum ornamentum pro soosan ruptor

- Sigillum Ornamentum pro General Breaker

- Sigillum Ornamentum pro Atlas Copco Breaker

- Sigillum ornamentum pro Daemo ruptor

- Sigillum ornamentum ad Toku ruptor

- Sigillum ornamentum pro Everdigm ruptor

- Sigillum ornamentum pro Rammer ruptor

- Sigillum ornamentum pro NPK ruptor

- Sigillum Ornamentum pro Konan Breaker

- Sigillum ornamentum pro HDB gratis

- Sigillum ornamentum pro Montabert Breaker

- Sigillum ornamentum denique ruptor

- Sigillum ornamentum Krupp ruptor

- Sigillum Ornamentum pro Okada Breaker

- Sigillum ornamentum pro malleo

- Sigillum ornamentum pro MSB Breaker

- Sigillum ornamentum de Huskie Breaker

- Sigillum ornamentum ad Toyo Raer

- Sigillum Kit ad KCB Breaker

- Sigillum ornamentum ad Teledyne ruptor

- Sigillum ornamentum pro stanly ruptor

- Sigillum ornamentum pro teisaku ruptor

- Sigillum ornamentum in Sandvik ruptor

- Sigillum Ornamentum pro Chicago ruptor

- Sigillum Ornamentum pro causa ruptor

- Sigillum Ornamentum pro Volvo Breaker

- Sigillum ornamentum pro Komac ruptor

- Sigillum ornamentum pro giant ruptor

- Sigillum ornamentum pro miraculo ruptor

- Sigillum Ornamentum pro Jisung ruptor

- Sigillum Ornamentum pro D & A Breaker

- Sigillum ornamentum pro daewoon ruptor

- Sigillum ornamentum in Boohung Breaker

- Sigillum ornamentum biline

- Sigillum ornamentum pro taesung ruptor

- Sigillum Kit for Majesta Breaker

- Sigillum ornamentum pro EDT ruptor

- Sigillum Ornamentum pro REDOX ruptor

- Sigillum ornamentum ad Powering ruptor

- Sigillum Ornamentum pro T & H Breaker

- Sigillum ornamentum pro Kwanglim Breaker

-

CAVATOR HYDRAULICUS SIMILIS SIMUL

- Sigillum Kit for Komatsu Excavator

- Sigillum ornamentum pro CAVAVATOR

- Sigillum ornamentum pro Volvo CAVATOR

- Sigillum ornamentum enim Hyundai Excavator

- Sigillum ornamentum pro Hitachi CAVATOR

- Sigillum Kit Kobelco CAVATOR

- Sigillum ornamentum enim Sumitomo Excavator

- Sigillum ornamentum Doosan Daewoo

- Sigillum Kit for JCB EXCVATOR

- Sigillum Kit ad Kato CULAVATOR

- Alius

- Backhoe oneratus sigillum ornamentum

- HYDRAULICUS Pump SAMON Kit

- Motor Hydraulica sigillum ornamentum

- Hydraulicas ruptor diaphragm

- CYMBALON

- Polyurethane damper

- HYDRAULICUS

-

Hydraulicorum Rudia Sigillum Ornamentum

- De nobis

- R & D

- Applicatio

- Rudis materia

- Nuntium

- Contact Us

- Login

-

Latine

-

Anglicus

Anglicus

-

Gallus

Gallus

-

Germanus

Germanus

-

Portuguese

Portuguese

-

Spanish

Spanish

-

Russian

Russian

-

Iaponica

Iaponica

-

Coreanica

Coreanica

-

Arabic

Arabic

-

Hibernica

Hibernica

-

Graeculus

Graeculus

-

Turkish

Turkish

-

Italiae

Italiae

-

DANICULUS

DANICULUS

-

Romanian

Romanian

-

Indonesiaca

Indonesiaca

-

Bohemica

Bohemica

-

Africikaans

Africikaans

-

SCELIDUS

SCELIDUS

-

POLICULO

POLICULO

-

Basque

Basque

-

Catalana

Catalana

-

Esperanto

Esperanto

-

Hindi

Hindi

-

Lago

Lago

-

Illyrica

Illyrica

-

Amharicus

Amharicus

-

Armeniana

Armeniana

-

Azerbaieni

Azerbaieni

-

Belarusian

Belarusian

-

Bengalica

Bengalica

-

BOSNIAN

BOSNIAN

-

Bulgarica

Bulgarica

-

Cebuano

Cebuano

-

Chichewa

Chichewa

-

Corsican

Corsican

-

Crovatica

Crovatica

-

Batavica

Batavica

-

Estonian

Estonian

-

Philippinica

Philippinica

-

Fennica

Fennica

-

Frisian

Frisian

-

Gallaeca

Gallaeca

-

Georgian

Georgian

-

Gujarati

Gujarati

-

Haitiaian

Haitiaian

-

Hausa

Hausa

-

HAWAIUS

HAWAIUS

-

Hebraica

Hebraica

-

Hmong

Hmong

-

Hungarian

Hungarian

-

IMETIANICUS

IMETIANICUS

-

Igbo

Igbo

-

Javanese

Javanese

-

Cannada

Cannada

-

Kazakh

Kazakh

-

Khmer

Khmer

-

Kurdica

Kurdica

-

Kyrgyz

Kyrgyz

-

Latine

Latine

-

Latvian

Latvian

-

Lithuanian

Lithuanian

-

Luxemburg

Luxemburg

-

Macedonian

Macedonian

-

MALAGASUS

MALAGASUS

-

Malae

Malae

-

Malayalam

Malayalam

-

Melitensis

Melitensis

-

Maorice

Maorice

-

Marathi

Marathi

-

Mongolica

Mongolica

-

Burmese

Burmese

-

Nepalica

Nepalica

-

Norwegian

Norwegian

-

Pastua

Pastua

-

Persicus

Persicus

-

Punjabi

Punjabi

-

Serbian

Serbian

-

Sesotho

Sesotho

-

Sinhala

Sinhala

-

Moravica

Moravica

-

Carnica

Carnica

-

Somali

Somali

-

Samoan

Samoan

-

Scoti Gaelic

Scoti Gaelic

-

Shona

Shona

-

Sindhi

Sindhi

-

Sundanese

Sundanese

-

Swahili

Swahili

-

Tajik

Tajik

-

Tamil

Tamil

-

Telugu

Telugu

-

Thai

Thai

-

Ucraina

Ucraina

-

Urdu

Urdu

-

Uzbek

Uzbek

-

Vietnamica

Vietnamica

-

Cambrica

Cambrica

-

Xhosa

Xhosa

-

LOKINDIS

LOKINDIS

-

Yoruba

Yoruba

-

Zuluensis

Zuluensis

-

Kinyarwanda

Kinyarwanda

-

Tatar

Tatar

-

Oriya

Oriya

-

Turkmen

Turkmen

-

Uyghur

Uyghur

-

- In domo

-

-

- Diaphragma enim Hyd. Ruptor

- Sigillum ornamentum in furukawa ruptor

- Sigillum ornamentum pro soosan ruptor

- Sigillum Ornamentum pro General Breaker

- Sigillum Ornamentum pro Atlas Copco Breaker

- Sigillum ornamentum pro Daemo ruptor

- Sigillum ornamentum ad Toku ruptor

- Sigillum ornamentum pro Everdigm ruptor

- Sigillum ornamentum pro Rammer ruptor

- Sigillum ornamentum pro NPK ruptor

- Sigillum Ornamentum pro Konan Breaker

- Sigillum ornamentum pro HDB gratis

- Sigillum ornamentum pro Montabert Breaker

- Sigillum ornamentum denique ruptor

- Sigillum ornamentum Krupp ruptor

- Sigillum Ornamentum pro Okada Breaker

- Sigillum ornamentum pro malleo

- Sigillum ornamentum pro MSB Breaker

- Sigillum ornamentum de Huskie Breaker

- Sigillum ornamentum ad Toyo Raer

- Sigillum Kit ad KCB Breaker

- Sigillum ornamentum ad Teledyne ruptor

- Sigillum ornamentum pro stanly ruptor

- Sigillum ornamentum pro teisaku ruptor

- Sigillum ornamentum in Sandvik ruptor

- Sigillum Ornamentum pro Chicago ruptor

- Sigillum Ornamentum pro causa ruptor

- Sigillum Ornamentum pro Volvo Breaker

- Sigillum ornamentum pro Komac ruptor

- Sigillum ornamentum pro giant ruptor

- Sigillum ornamentum pro miraculo ruptor

- Sigillum Ornamentum pro Jisung ruptor

- Sigillum Ornamentum pro D & A Breaker

- Sigillum ornamentum pro daewoon ruptor

- Sigillum ornamentum in Boohung Breaker

- Sigillum ornamentum biline

- Sigillum ornamentum pro taesung ruptor

- Sigillum Kit for Majesta Breaker

- Sigillum ornamentum pro EDT ruptor

- Sigillum Ornamentum pro REDOX ruptor

- Sigillum ornamentum ad Powering ruptor

- Sigillum Ornamentum pro T & H Breaker

- Sigillum ornamentum pro Kwanglim Breaker

-

- Sigillum Kit for Komatsu Excavator

- Sigillum ornamentum pro CAVAVATOR

- Sigillum ornamentum pro Volvo CAVATOR

- Sigillum ornamentum enim Hyundai Excavator

- Sigillum ornamentum pro Hitachi CAVATOR

- Sigillum Kit Kobelco CAVATOR

- Sigillum ornamentum enim Sumitomo Excavator

- Sigillum ornamentum Doosan Daewoo

- Sigillum Kit for JCB EXCVATOR

- Sigillum Kit ad Kato CULAVATOR

- Alius

-

-

-

-

CYMBALON>

-

-

-

- De nobis

- R & D

- Applicatio

- Rudis materia

- Nuntium

- Contact Us

- Login

Rudis materia progressionem

MDI

Physical properties Test standard Unit Value Hardness ASTM D2240 shore A 95 Hardness ASTM D2240 shore D 51 Density ASTM D792 g/cm3 1.19 Tensile strength ASTM D412 (500mm/min) MPa 50 100% modulus ASTM D412 (500mm/min) MPa 14.5 300& modulus ASTM D412 (500mm/min) MPa 26 Elongation at break ASTM D412 (500mm/min) % 420 Tear strength ASTM D264 (500mm/min) N/mm 145 Abrasion DIN 53516 mm3 29 Compression set (70℃ 24H) ASTM D395 (Method B compression rate 25%) % 21 Compression set (100℃ 24H) ASTM D395 (Method B Compression 25%) % 33 Low temperature shrinkage TR10 GB / T7758 - MMII ℃ - Low Temperatus DECREMENTUM TRIC3 GB / T (VII) DCCLVIII - MMII ℃ - 15.7 humilis temperatus DECREMENTUM TR50 GB / T (VII) DCCLVIII - MMII ℃ -

Materia parametri

Physica proprietatibus test vexillum unitas valorem

D2240 ASTM D2240 Litus a XCVI

D2240 D2240 D2240 D LI

Density ASTM D792 G / CM3 1,19

Tensile Fortis ASTM D412 (500mm / min) Mpa XLII

C% modulus ASTM D412 (500mm / min) MPA 14.5

CCC & modulus ASTM D412 (500mm / min) MPA XXVI

Elongatio ad confractus ASTM D412 (500mm / min) CDXX%

Lacrimam vires ASTM D264 (500mm / min) N / mm CXLV

AMMINUM DIN (LIII) DXVI MM3 XXIX

Cogo Set (LXX ℃ 24H) ASTM D395 (Modum B. compressionem rate XXV%) XXI% XXI

Cogo Set (C ℃ 24h) ASTM D395 (Ratio B. Compressio Rate XXV%) XXXIII%

Minimum Temperatus DECREMENTUM TR10 GB / T7758 - MMII ℃ - XXIV

Minimum Temperatus DECREMENTUM TRIC3 GB / T (VII) DCCLVIII - MMII ℃ - 15,7

Minimum Temperatus DECREMENTUM TR50 GB / T (VII) DCCLVIII - MMII ℃ - 9,8

Material application missionibus

Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, Phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃, working temperature: POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃, working temperature: POM -30-100 ℃, phenolic resin PF -55-120 ℃, repleti ptfe + XL% aeris pulveris - CC - CCLX ℃, working temperatus: pom - XXX - Cf ℃, phenolic resinae pf - LV% aeris pulveris - CC - ℃

- Support technica

- Industria solutions

- Technical Support Analysis

Copyright © MMXXII, omnes Right Reserved © Borise Technology Co., Ltd

Calidum products-Sitemap

Gas caligarum rubber sigillum,Sigillum Kit Pump,sigillum ornamentum hydrau,Sigillum illud ornamentum,Causa Hydraulica cylindrum instaurabo Kits,6657024 Sigillum Ornamentum

Support technica

Copyright © MMXXII, omnes Right Reserved © Borise Technology Co., Ltd

Calidum products-Sitemap

Gas caligarum rubber sigillum,Sigillum Kit Pump,sigillum ornamentum hydrau,Sigillum illud ornamentum,Causa Hydraulica cylindrum instaurabo Kits,6657024 Sigillum Ornamentum